Coolant pressure gauging-kit for precise pressure measurement – exactly where it counts.

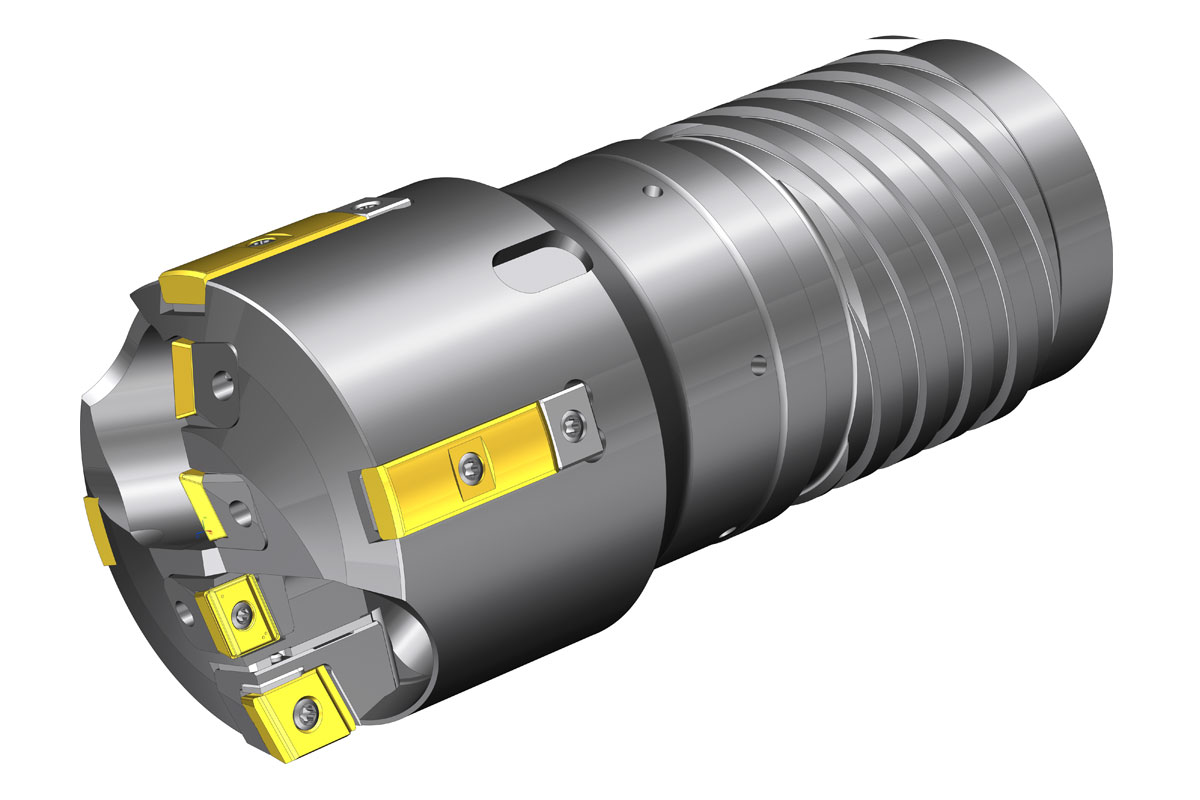

The pressure measurement system developed by botek determines the actual pressure directly at the spindle outlet or at the tool – up to 160 bar!

The cooling channel size of the tool is also taken into account – for precise and reliable measurement results that create full transparency.

Detect hidden causes at an early stage

Problems such as leaking valve parts, damaged rotary feeds, kinked or excessively long hose lines and worn pumps often remain undetected – but lead to pressure losses and impair drilling performance and tool life.

With the botek coolant pressure gauging-kit, these weak points can be detected quickly and accurately.

Advantages:

– Fast and targeted fault diagnosis

– Optimization of drilling processes

– Longer service life of your tools

– Avoidance of unplanned machine downtimes